According to a report by Bank of America Securities, India is set to construct more national highways in the decade up to 2025 than it did from 1950 to 2015 combined. The highway construction industry is projected to experience an impressive 133% growth by the year 2025. As the rate of road construction increases, the demand for road construction machinery will also rise. Understanding road construction machinery and its various types is essential as it allows for the effective use of equipment, resulting in smoother construction processes. These machines form the backbone of road construction, facilitating everything from excavation to paving and maintenance.

Familiarity with different types ensures efficient project planning, execution, and, ultimately, the creation of safe and durable roadways. In this article, we'll discuss the various types of road construction machinery and what are the benefits of selecting the right machinery for the project.

Exploring the diverse range of road construction machinery is essential for understanding the intricate processes involved in building and maintaining road infrastructure. Here are some of the major types of road construction machinery:

An asphalt batching plant, also known as an asphalt mixing plant, is a crucial facility in road construction for producing asphalt mixtures. It combines various aggregates, filler materials, and asphalt binder in precise proportions to create hot mix asphalt (HMA) used for paving roads, highways, and other surfaces. The plant typically consists of several components, including cold aggregate feeder bins, a drum dryer, a mixing chamber, hot bins, and a control system.

Application:

Asphalt batching plants are vital for producing high-quality asphalt mixtures used in road construction projects. They are used to manufacture various types of asphalt mixes, including dense-graded, open-graded, and stone matrix asphalt, to meet specific project requirements.

Asphalt pavers are heavy equipment machines used to lay and compact asphalt pavement on roads, highways, and other paved surfaces. They receive hot mix asphalt from trucks and distribute it evenly across the surface using a screed or paving machine. Asphalt pavers come in various configurations, including wheeled and tracked models, with adjustable paving widths to accommodate different project specifications. They play a critical role in achieving smooth, uniform, and durable asphalt surfaces for road infrastructure.

Application: Asphalt pavers are essential for laying asphalt pavements during road construction projects. They are used to pave roads, parking lots, driveways, and other paved areas, ensuring the proper compaction and smoothness of the asphalt surface.

Road rollers are heavy machinery used for compacting soil, gravel, asphalt, or concrete surfaces. They exert pressure to increase material density, improving load-bearing capacity and reducing the risk of settlement or deformation. Road rollers come in various sizes and configurations, including smooth drum rollers for asphalt compaction and padfoot rollers for compacting cohesive soils. They are essential in road construction projects to achieve the required density and smoothness of road surfaces.

Application: Road rollers are used for compacting soil, gravel, asphalt, or concrete surfaces to increase their density and stability, improving the load-bearing capacity and longevity of the road.

Motor graders are specialized machines designed for fine grading and leveling of road surfaces. They feature a long blade that can be adjusted to achieve the desired slope and smoothness, ensuring proper drainage and safe driving conditions. Motor graders are equipped with wheels or tracks for mobility and stability, allowing them to operate effectively in different terrains and conditions. Motor graders are essential for maintaining road integrity and surface quality.

Application: Graders are essential for fine grading and leveling of road surfaces, ensuring proper drainage and smoothness for safe and efficient driving conditions.

A milling machine, also known as an asphalt milling machine, is used to remove the top layer of asphalt or concrete from roads and other paved surfaces. It consists of a rotating drum with teeth that grind and remove the pavement material, which is then collected by a conveyor system for disposal or recycling. Milling machines are essential for pavement rehabilitation and maintenance, helping to restore the smoothness and evenness of road surfaces.

Application: Milling machines are primarily used for pavement milling and profiling tasks during road construction and maintenance projects. They are used to remove worn-out or damaged pavement layers, correct surface irregularities, and prepare the road surface for resurfacing.

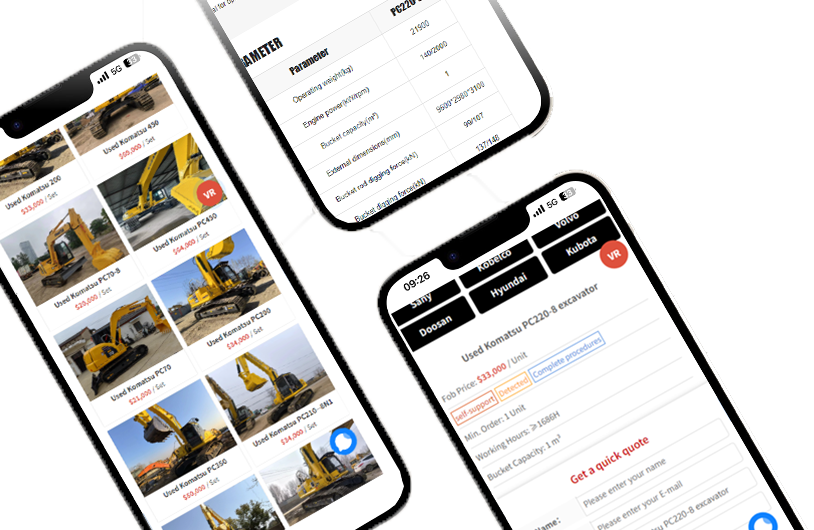

A crawler excavator is a versatile earthmoving machine with tracks for stability and mobility. It features a hydraulic arm and bucket attachment for digging, trenching, and material handling tasks in road construction. Its ability to operate in various terrains makes it essential for excavating and shaping roadways.

Application: Excavators are used for digging trenches, foundations, and holes, as well as for material handling, demolition, and landscaping during road construction projects.

Truck cranes are mobile lifting machines mounted on trucks for transporting and lifting heavy loads. They feature a telescopic boom and hydraulic system for hoisting and maneuvering loads during road construction projects. Truck cranes are essential for tasks such as placing bridge girders, installing signages, and lifting equipment.

Application: Truck cranes are used for tasks such as placing bridge beams, installing overhead signages, and lifting heavy machinery or prefabricated components.

Choosing the appropriate machinery can streamline operations, improve efficiency, and ensure the quality and durability of the road infrastructure. Here are some benefits of selecting the right road construction machinery:

Properly chosen machinery can optimize workflow, reducing downtime and completing tasks more efficiently. For example, using a bulldozer for land clearing instead of manual labor speeds up the process significantly.

The right machinery can help minimize operational costs by reducing labor expenses and maximizing productivity. Investing in high-quality equipment may have a higher upfront cost but can result in long-term savings through improved performance and durability.

Modern road construction machinery often comes with advanced safety features, reducing the risk of accidents and injuries on the job site. For instance, automated warning systems on compactors can alert operators of potential hazards, enhancing overall safety.

Choosing the appropriate machinery ensures that tasks are completed with precision and accuracy, leading to higher-quality road infrastructure. For example, using a grader for surface leveling produces a smoother road surface, reducing the need for costly repairs and maintenance later on.

In conclusion, road construction machinery comprises a diverse range of equipment essential for building and maintaining robust infrastructure. Understanding the various types of machinery helped in informed decision-making optimizing efficiency, safety, and quality in road construction projects.

Operating weight(Tons): 36

Working Time(Hours): ≥3150

Bucket capacity(m³): 1.5